November 18, 2024

Editors' notes

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Machine learning aids rapid advancement of a high-resolution 3D printing technology

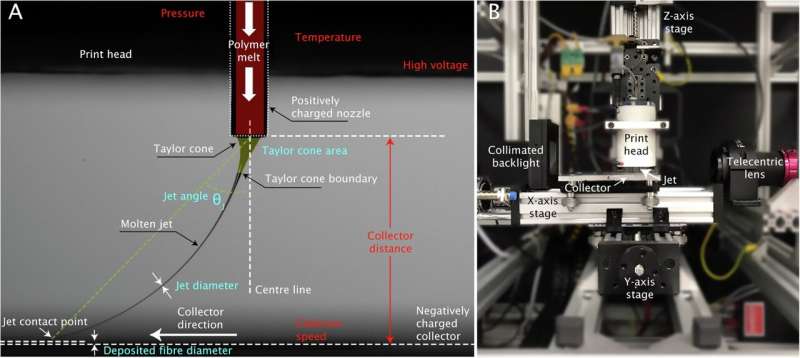

QUT biomedical engineers have developed a new automated method to drastically advance melt electrowriting, a new, high-resolution 3D printing technology used in tissue engineering and regenerative medicine.

First author Dr. Pawel Mieszczanek, who did his Ph.D. in the ARC Training Center in Additive Biomanufacturing at QUT, said the method would enable faster advancement of melt electrowriting (MEW) technology.

"MEW is a multifaceted 3D printing technology that also has applications in bioengineering, biomaterials science, and soft robotics," Dr. Mieszczanek said.

"However, it has faced many challenges from its early stages more than 10 years ago to its current stage, hampered by long experimentation times, low printing speeds, poor consistency in results, and dependence on the user for printer operation.

"To address these problems, we used machine learning (ML) to create a closed-loop process control system for MEW.

"The novel MEW system design is effective because it monitors the fiber-flight pass, allowing us to use real-time imaging for continuous analysis."

Distinguished Professor Dietmar W. Hutmacher, director of the Max Planck Queensland Center (MPQC) for the Materials Science of Extracellular Matrices, based at QUT, said the new automated data collection system reduced the experimental time to hours instead of days and weeks.

"We use a feedforward neural network, optimization techniques, and feedback loop to ensure that printed parts are consistently reproducible.

"This work shows that machine learning can automate MEW operations and support the engineering of effective closed-loop control in complex 3D printing technology."

The research team comprised Dr. Pawel Mieszczanek, Distinguished Emeritus Professor Peter Corke, Distinguished Professor W. Hutmacher, all from QUT; Professor Courosh Mehanian and Associate Professor Paul D. Dalton from the University of Oregon.

The study, "Towards industry-ready additive manufacturing: AI-enabled closed-loop control for 3D melt electrowriting," was published in Communications Engineering.

More information: Pawel Mieszczanek et al, Towards industry-ready additive manufacturing: AI-enabled closed-loop control for 3D melt electrowriting, Communications Engineering (2024). DOI: 10.1038/s44172-024-00302-4

Journal information: Communications Engineering Provided by Queensland University of Technology Citation: Machine learning aids rapid advancement of a high-resolution 3D printing technology (2024, November 18) retrieved 19 November 2024 from https://techxplore.com/news/2024-11-machine-aids-rapid-advancement-high.html This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.

Explore further

Machine learning enhances defect detection in metal 3D printing 21 shares

Feedback to editors